All Crouzet Structural Monitoring Sensors offer

30+ years designing & manufacturing structural monitoring sensors.

Crouzet has been designing and manufacturing all types of force transducers and electronic conditioners for 30 years.

Crouzet also offers services (instrumentation) for the measurement, control and monitoring of your industrial processes, equipment and structures. With our extensive experience and design office, Crouzet can bring you specific solutions that comply with your specifications, while respecting both your technical and financial constraints.

Your purchase of a Crouzet force testing transducer or force testing system will provide you with a quality product adapted to your application environment, additional services, technical support and real-time monitoring.

Why choosing Crouzet?

Dedicated custom solutions to suit your design requirements

10 manufacturing plants around the world

Partners with market leaders

30+ years’ experience in structural monitoring sensors

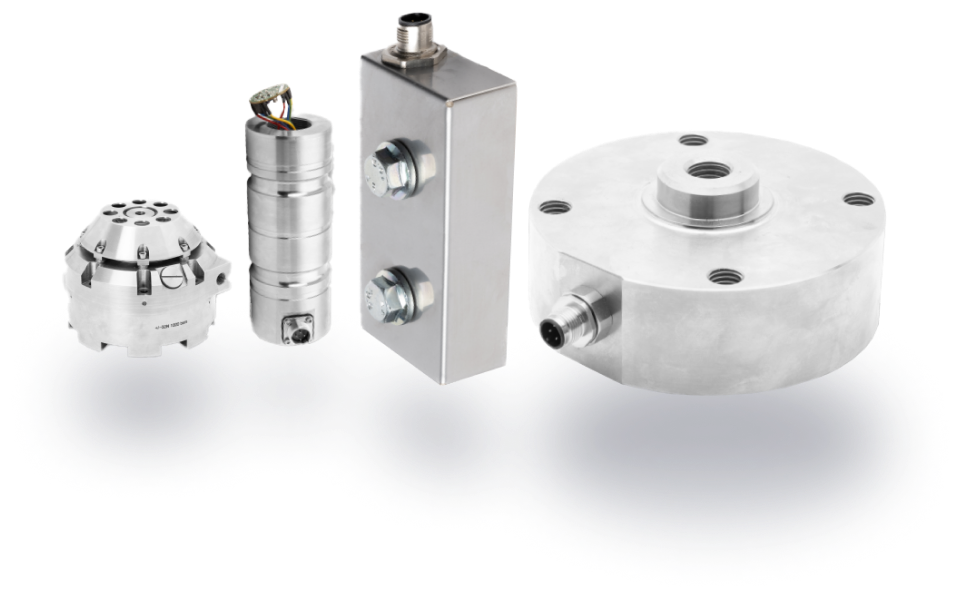

Get to know the full offer

Driven by innovation, our experts are focused on designing and delivering the right product for the right application.

Custom electronic boards, sensors and conditioners designed for your applications

30 years of customization, adaptation & co-design expertise at your service.

Our design office examines all your requests and specific needs, bringing you customised solutions adapted to your requirements, the constraints of your sector and your applications; all according to your specifications.

A Team of Experts.

Designing customised solutions with leaders in the aeronautical and railway sectors.

Powerful tools.

Numerous calibration or acquisition tools available to our clients.

Nearby Geographical Proximity.

Our teams of experts can travel around the world to meet your needs. Our teams of experts can travel around the world to meet your needs.

Technical Expertise.

Know-how and technical expertise acquired over 30 years.

Services

Our engineers examine all your specific requests and needs, to offer you tailor-made solutions, adapted to your requirements and the constraints of your sector, according to your specifications and your application.

Calibration

CROUZET can perform COFRAC-connected calibration of your force and torque sensors. CROUZET can draw on its expertise and testing facilities to conduct fatigue tests.

Tell us about your needsFunctions.

Realization of your calibrations whatever the type of your sensors, whatever your instrumented parts, ensuring a precise and stable measurement.

Certifications.

ISO 9001 Certified All our calibration presses are connected to the SI (International System of Units)

Our means of calibration.

– Fatigue presses

– Traction & Compression presses

– Torque benches

Acquisition capacity.

– Dynamic acquisition system: 100 KHz, 32 tracks.

– Static acquisition system: up to 2000 Hertz, more than400 tracks.

Reparation

CROUZET can repair your damaged sensors.

Tell us about your needsFunctions.

Crouzet offers to repair your damaged sensors, whether they are Crouzet sensors or not. A customized solution that meets your needs.

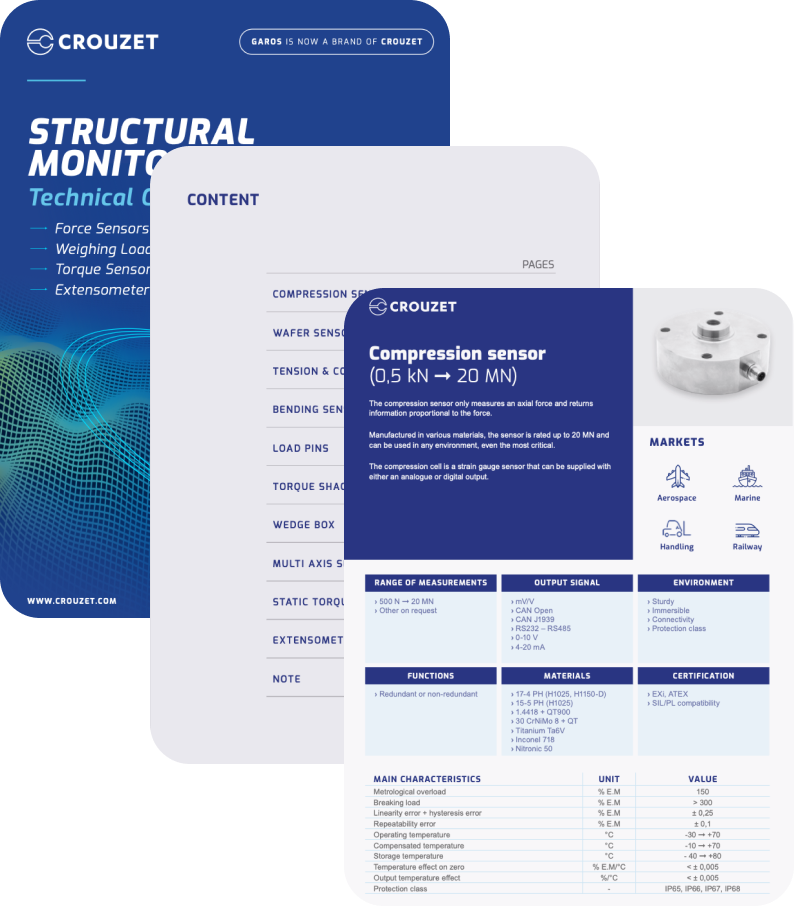

Full Product Selection Guide

If you want to choose the product that matches your specific needs, view our solutions

Market application

Sensor bonding services

In order to measure structural force on pieces or equipment. Crouzet integrates thousands of strain gauges in order to measure the deformation or temperature during tests.

Crouzet provides sensor bonding services to OEMs and manufacturers to measure structural forces and stresses on parts (propeller, actuator), aircraft or car. Dozens or even thousands of sensors are glued to the aircraft or vehicle during testing to measure strain or temperature and ensure the integrity and reliability of the structure.

The 4 main steps

Selection.

Selection of the most appropriate type of sensor.

Gluing of gauges.

Precise and rigorous gluing of gauges for measurement of deformation points.

Data acquisition.

Data acquisition (temperature, deformation, accelerometer, noise, pressure).

Data analyses.

Collected data analysis and processing.

Market applications

Aerospace and defense

- Flight and ground tests on aircraft

- Fatigue strain measurement on aircraft wings

Railway

- Measurement of the incoming forces on the wheels.

- Comfort analysis, vibration analysis – accelerometers

- Automatic train acceleration/deceleration control.

- Load measurement on the trailer hitch.

Automotive

Crash tests for racing cars

Infrastructure

- Railway surveillance:

- Tunnel

- Bridge

- Track and overhead lines

- From the sensors on the rails to the exploitation of the acquired data, for the monitoring of the railroads

- Measurement of force on the railroad track

- Control of track and rail deformation

Garos, a brand of Crouzet

Since February 2019, automated system specialist Crouzet has integrated the sensors, electronics and instrumentation activities of Garos and is rolling out its external growth and development plan. Crouzet is an independent manufacturer of mechatronic components for critical applications in the Aerospace and Transportation, Energy, Building and Machine Building industries.

Crouzet

GAROS

Incorporation of GAROS